Particle distribution affects how your product looks and feels. When particles are evenly spread, products appear clearer and smoother because light passes through easily and fewer particles cause cloudiness. Achieving uniform distribution involves techniques like stirring or agitation that keep particles suspended and prevent settling. Environmental factors, like movement or stillness, also play a role in maintaining this balance. If you explore further, you’ll discover how science controls these behaviors to improve product quality and clarity.

Key Takeaways

- Uniform particle distribution minimizes light scattering, enhancing clarity and transparency in liquids and suspensions.

- Non-uniform distribution causes particles to aggregate or settle, leading to cloudiness or haziness.

- Techniques like agitation and homogenization promote even dispersion, improving product appearance and consistency.

- Environmental factors such as movement and gravity influence whether particles stay suspended or settle over time.

- Controlled particle dynamics ensure desirable texture, visual clarity, and functional properties in various industries.

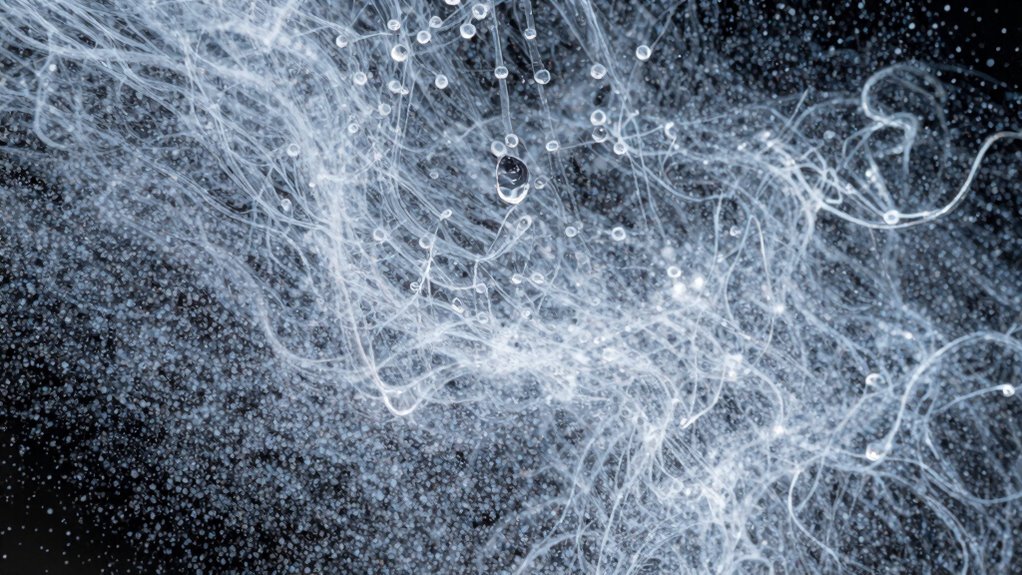

Have you ever wondered how particles spread out in different environments? It’s a fascinating process driven by particle dynamics, which describes how individual particles move, collide, and settle over time. Understanding these dynamics helps explain why some substances appear clear and smooth, while others have a more textured or cloudy look. Central to this is the concept of distribution uniformity—the degree to which particles are evenly spread. When particles distribute uniformly, the result tends to be clearer and more consistent, enhancing the clarity and perceived quality of a liquid or material.

In any environment, particles are constantly in motion, influenced by factors like temperature, pressure, and the medium they’re in. These factors dictate their speed and direction, leading to different patterns of distribution. For example, in a well-mixed solution, particles collide frequently, bouncing around and spreading out evenly. This high level of distribution uniformity produces a transparent appearance because there are fewer regions with high concentrations of particles that could scatter light or create opacity. Conversely, if particles are clumped together or settle unevenly, the distribution becomes non-uniform, resulting in cloudiness or a hazy quality that diminishes clarity.

Your understanding of particle dynamics reveals that achieving a uniform distribution is often the goal in industries like beverage production, cosmetics, or pharmaceuticals. To attain this, processes such as agitation, stirring, or homogenization are employed. These techniques break apart particle clusters and distribute them evenly throughout the medium. When done effectively, the particles remain suspended uniformly, maintaining a consistent texture, appearance, and transparency. This uniformity not only influences visual clarity but also affects how the product feels and functions. For instance, a lotion with well-dispersed particles feels smooth, while one with uneven distribution might feel gritty.

The science behind particle distribution also explains how different environments lead to varied outcomes. In still water, particles tend to settle or form layers due to gravity, creating non-uniform distribution over time. But in dynamic environments with constant movement, particles stay dispersed, maintaining high distribution uniformity. This principle applies across many fields, from designing clearer beverages to creating stable emulsions. By controlling particle dynamics, scientists and engineers can optimize the clarity and body of a product, ensuring it meets specific quality standards.

In essence, understanding particle dynamics and distribution uniformity allows you to see how microscopic behaviors influence the macroscopic properties you observe. Whether it’s a glass of crystal-clear water or a creamy cosmetic, the way particles move and spread determines its clarity and body. This knowledge empowers you to appreciate the science behind everyday products and highlights the importance of controlling these factors to achieve desired results.

Frequently Asked Questions

How Do Particle Sizes Affect Product Clarity and Body?

Smaller particle sizes improve formulation clarity because they scatter less light, making the product look smoother and more transparent. Conversely, larger particles can create a cloudy or gritty appearance, reducing clarity. Particle size also influences body; larger particles add thickness and texture, while smaller particles make the product feel lighter and more uniform. By controlling particle size, you can optimize both clarity and body for your finished product.

Can Particle Distribution Be Modified After Manufacturing?

Yes, you can modify particle distribution after manufacturing through adjustments in particle consistency, such as blending, milling, or adding stabilizers. These manufacturing processes help refine the particle size and improve uniformity, enhancing product clarity and body. By carefully controlling these steps, you can achieve the desired texture and appearance, ensuring your product meets quality standards even after initial production.

What Tools Are Used to Measure Particle Distribution Accurately?

You can measure particle distribution accurately using tools like spectroscopy techniques and laser diffraction. Spectroscopy techniques analyze how particles interact with light, providing detailed insights into their size and composition. Laser diffraction uses a laser beam to measure how particles scatter light, giving precise size distribution data. These methods help guarantee quality control and consistency in manufacturing processes by providing reliable, real-time particle size information.

How Does Temperature Influence Particle Stability in a Formulation?

Think of your formulation as a delicate dance where temperature acts as the conductor. When it rises, nano scale effects can cause particles to collide and clump, reducing thermal stability. Cold temperatures keep particles evenly distributed and stable, ensuring clarity and consistency. So, controlling temperature is essential—too hot, and particles may destabilize; too cold, and the formulation might become too viscous. Maintaining ideal temperature preserves particle stability effectively.

Are There Environmental Factors Impacting Particle Distribution Over Time?

Environmental factors like air quality and environmental stability substantially impact particle distribution over time. Poor air quality introduces pollutants that can cause particles to aggregate or settle unevenly, altering the formulation’s clarity and consistency. Fluctuations in temperature and humidity also affect stability, potentially leading to particle migration or separation. You should monitor and control these environmental conditions to maintain ideal particle distribution, ensuring product quality and longevity.

Conclusion

Understanding particle distribution is like tuning a perfect symphony, where each note plays its part in creating clarity and body. When particles are evenly spread, your visuals become sharp and full, much like a well-conducted orchestra. Remember, just as every instrument matters, every particle shapes the overall experience. By mastering this science, you’re orchestrating a clearer, richer picture—turning complexity into harmony, and confusion into beautiful clarity.